Manufacturing in the field

FACTORY

FACTORY

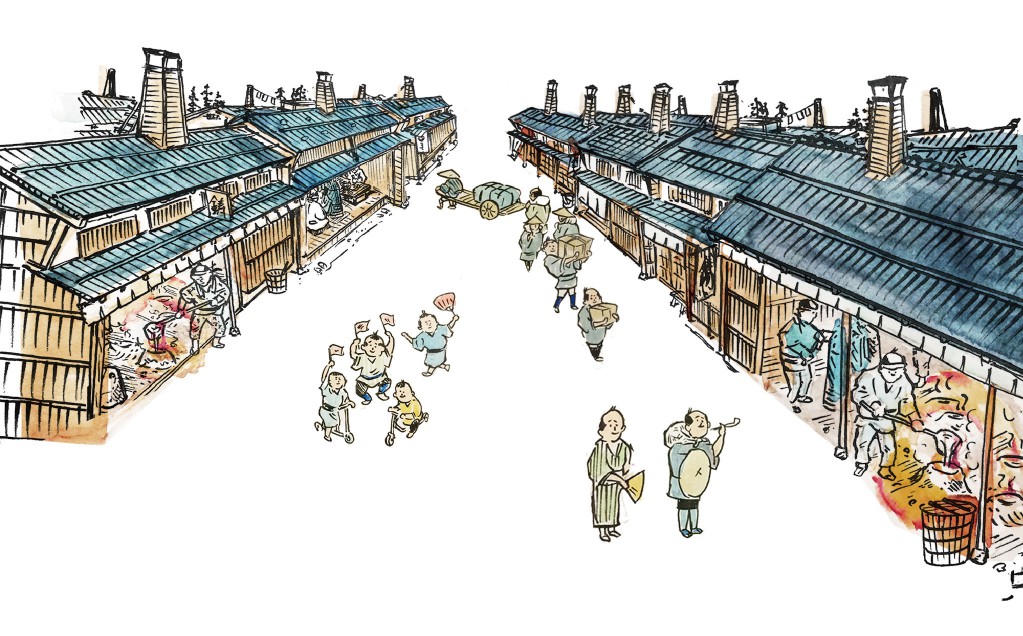

Manufacturing in Takaoka got its start when Lord Maeda Toshinaga founded the town about 400 years ago. At that time, he invited a wide range of craftspeople to the town, including seven skilled casters, who began by making cast metal implements for daily life. Their copperware manufacture thrived from the mid-Edo Period. Takaoka copperware has been designated a traditional handcraft by the Japanese government. It currently holds the leading share in the nationwide market.

Takaoka lacquerware, also designated a traditional handcraft by the government of Japan, began with furniture production. Over the years, techniques unique to Takaoka emerged, including yusuke-nuri lacquerware, chokoku-nuri lacquerware, and aogai-nuri lacquerware (objects featuring inlaid mother of pearl). During the Meiji Period, Takaoka was among Japan’s leading lacquerware-producing regions. Even today, it accounts for roughly 90% of the Japanese market for objects featuring inlaid mother of pearl.

Drawing on traditional techniques, Takaoka is currently home to a wealth of state of the art manufacturing. It’s also characterized by advanced industrial specialization associated with highly skilled craftspeople. Individual factories and studios offer tours and hands-on activities, creating excellent opportunities to see and experience manufacturing workplaces up close and to rediscover some remarkable things about Takaoka.

Making metal more beautiful, working carefully by hand.

ONO Polish Works.

This is one of the finishing processes for metal casting, and covers the polishing section. Buff polishing is performed manually by hand, mainly on metal products, such as arts and crafts, and works of art etc. Buff polishing is a surface processing polishing technique and involves rotating a cloth or rubber buff wheel attached to a rotating motor machine, which polishes by pressing up against the target item while applying an abrasive agent. This covers the range from machining to mirror polishing. It is well renowned for the beauty of the finishing, in which each work is carefully adjusted based on the feel of the craftsman’s fingertips.

46-1-2 Tidesakae-machi, Takaoka-city,Toyama-prefecture

TEL. 080-3047-1908

Traditional and, yet, innovative factory perpetually aiming at profound possibility of the sound of metals.

KOIZUMI SEISAKUSHO Co., Ltd.

Established in Meiji 22, our factory has been dealing with copper alloy casting and processing. We are especially good at developing sound crafts; our products “Orin” (a kind of hand bell) and desk bel, which makes best use of the charming sound of metals, got good design awards. In addition, we are making various original brand “KOIZUMIYA” goods all of which deal with “the very comfortable sounds”. We use the latest techniques such as 3D printer, modelling machine, laser marking, etc. In this way, we surely treasure the traditional Takaoka-Copper products making method that has more than 400 years’ history, and, yet, we are trying to employ innovative products making techniques.

You are welcome to see our factory and join the workshop to experience making a tin plate or sake cup.

Takaoka Window into Manufacturing: Re-imagining Wholesale

SHIKKI KUNIMOTO

Reopening 4/20!!

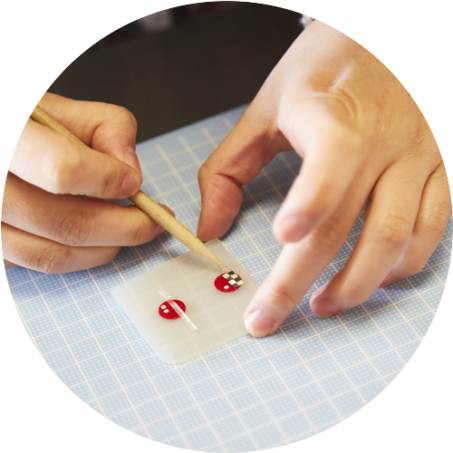

This is a lacquerware store that was founded in 1909, and sells products from all regions of Japan, particularly from Takaoka Lacquerware. In addition to our retail operations, we also design, manufacture and sell our own original products. With our QUILT tray series, which combines modern design with traditional carved lacquer, and our Jewel-3D RADEN COLLECTION series of accessories, made with Mother of Pearl, we combine the technique of Takaoka craftsmen to produce “useable” manufacturing. At our branch located in Yamachosuji, a district that flourished as the capital of commerce in the Edo period, we sell a variety of carefully selected products, ranging from traditional crafts to the works of young writers. You can also enjoy a variety of workshop experiences, such as making products with Mother of Pearl or Gold Leaf.

64 Konmadashi-machi, Takaoka-city,Toyama-prefecture

TEL. 0766-21-0763(Closed Wednesday )

Skilled techniques for the production of Buddhist equipments and large scale monuments, and the restoration of national treasures

KAJIHARA SEISAKUSHO Ltd,.

In the foundry established in 1902, the company offers total production ranging from planning & designing, and production (a master pattern, molding, finishing, coloring) to construction and installation. Utilizing various casting methods from the traditional techniques to the latest technologies, they can accommodate a wide range of requests such as large Buddhist statues, bronze statues, monuments, Buddhist bells, signage, and Buddhist equipments. The company is also involved with the replication and restoration of national treasures. The works by the skilled craftsmen can be found everywhere in and out of Japan including famous sights such as Sensoji Temple, Mt. Koya, the Tama Mausoleum of Emperor Showa.

3-3-22 Yokotamachi,Takaoka-city,Toyama-Prefecture

TEL. 0766-23-0279

Expressing freely while utilizing the traditional beauty and traditional high skills

YOTSUKAWA SEISAKUSYO Ltd.

A third generation cast-metal manufacturer in Kanaya-machi, they run 2 brands, “Kisendo” that gracefully expresses the Japanese traditional beauty with the traditional high skills of Takaoka copperware, and a lifestyle brand, “KISEN” that makes use of the good feature of metals with free ideas. They currently conduct marketing and product planning in-house as well as creation as a fabless maker to outsource production to other cast-metal manufacturers that have high skills of Takaoka. They have held many exhibitions not only in Japan but also overseas and have also won awards. They run the gallery “Tatara-an Kisen” located on a stone paved street as well as a showroom.

Continuing to create new value by leveraging their metal stamping technology

SEO Inc.

A rarity in the Takaoka copperware region mainly known for its castings, SEO inc. specializes in two types of metal stamping technologies, which are forging presses and sheet metal presses. Not only do they perform every step of the production process including finishing tasks such as polishing and welding, and their own packaging by themselves, but they have also started developing and marketing their own product brand. Their two brands, named “Sotto” (Buddhist altar fittings) and “Rain Chain” (decorative downspout), are beautifully designed to harmonize with modern home architecture, and have received Good Design awards, drawing attention from many quarters.

The shops and studio workshops which is recommended to visit in Kanaya-machi.

CASTING FACTORY RISABURO

The warkshop run by the generations of the Jinpachi family since the early Meiji period – they continue to produce cast products using the oldest method of metal casting, “two mold casting” as well as adopting new technologies. They sell Takaoka casting products created in this workshop or locally and also offer a workshop where you can experience curving the decorative patterns of your choice on the mold and pouring tin into a sand cast. Behind the shop are the workshop house and warehouse build in the early Meiji period, and it shows how the cast production scenery of the Showa period was. There is also “Petit Gallery – Yuzura” that displays and sells works of artists of various genres from in and out of the prefecture.

Creating a wide range of patterns in metals using traditional metal carving techniques

WADA CHOUKIN KOUBOU

The job of a metal carver involves using hammers and many different types of chisels to produce a diverse range of patterns in metal, including patterns that depict the beauties of nature, text, and crests. Sometimes this involves chiseling deep carvings; at other times, it involves creating delicate lines. While this studio produces mainly Buddhist altar fittings, it also makes commemorative items and repairs old metal carvings at client request. It even makes unusual items like dolls for the Boys’ Festival based on anime motifs. It’s truly capable of handling a wide range of metal-carving jobs. It also offers inlay work as well as coloring work using brush plating in gold, silver, and copper.

3-2 Omachi,Takaoka-city,Toyama-Prefecture

TEL. 0766-28-2872

A comforting sound that recalls the sounds of nature

YAMAGUCHI KYUJO Co., Ltd.

This facility first opened in 1907. While producing mainly temple and shrine fittings and artistic copperware, it also offers its own Kyujo Orin brand of rin bells used as Buddhist altar fittings, expanding their uses to a wide range of situations. The sound of a Kyujo Orin has a 1/f fluctuation that’s been reported (by Japan Acoustic Lab) to induce alpha brain waves, with healing effects. In the showroom, you can hear and buy more than 100 types of rin, including ones patterned on the 12 signs of the Chinese zodiac and small items that fit into the palm of your hand.

Large cast-metal objects from statues of Buddha to contemporary art

HEIWA GOKIN

From its establishment in 1909, this facility produced items like flower vases, tea ceremony utensils, and Buddhist altar fittings. But since the period following World War II, in response to growing demand for artistic cast-metal objects, it’s worked mainly on large items like copper statues, Buddha statues, and monuments. Since it offers a wide range of casting techniques accumulated over the changing times, many customers today are contemporary artists. It recently tackled the challenge of producing items in complex shapes through what’s known as precision casting. It also offers factory tours; the highlight of this tour, the casting process, in which metal heated to 1,300ºC is poured into a mold, is a must-see.

An integrated production structure from casting through finishing

DOGU

This maker of cast metal items was founded in 1899. It delivers full support with painstaking care for a wide range of products, from one-off items to mid-level mass production; from semi-order-made items to ones designed in house to meet specific customer needs.

In addition to applying, in the way best suited to each project, the techniques of greensand molding and a self-hardening mold process using binder mixed with sand to harden materials, the establishment offers the RIM resin molding technique, which employs special-purpose tools, as well as a finishing section that specializes in artistic cast-metal objects. The facility draws on a wealth of expertise on advanced techniques and cast-metal objects to produce a wide range of items. It also offers factory tours and hands-on casting events.

Lending the texture of contemporary life to the beauty of lacquerware

ALBEKY COMPANY

This facility applies nearly 400 years of lacquerware skills, inherited by the third-generation head of a chokoku-nuri (sculpture painting) lacquerware family business, to propose and deliver textures that have a beautiful feel, representing subjects like leaf veins, flowing water, and clouds drifting in the sky. In addition to painting wooden scriptures, this facility combines this technique with traditional Japanese washi paper, cloth, and gold foil to create patterns that take advantage of a broad range of techniques, including how chisels are used, how washi is given its crumpled texture, and how cloth is braided. It receives numerous orders from the construction industry for interior furnishings, signs, and other work, in addition to its traditional repertoire of wooden bowls, trays, and Buddhist altars. Those wishing to tour the factory are encouraged to contact it in advance.

A new world created with flexible wares made of 100% tin

NOUSAKU

Founded in Takaoka in 1916, Nousaku Corporation is a maker of cast-metal objects. Although Nousaku got its start making products like Buddhist altar fittings and tea ceremony utensils, flexible wares made of 100% tin have emerged as a big hit in recent years. It operates boutiques directly in locations across Japan, including leading department stores like Nihonbashi Mitsukoshi and Matsuya Ginza in Tokyo and Hankyu Umeda in Osaka. It continues to apply metal-casting techniques to tackle various other new challenges, including the production of medical implements and collaborative efforts with artists. A new office building and factory acting as a central point for industrial sightseeing was completed in April 2017. In addition to providing a cafe and a place to experience tin cast making, you can also observe the way craftworkers actually engage in manufacturing close up.

Photo by Tamotsu Kurumada

A delicacy and brilliant colors that give new life to the everyday

MOMENTUM FACTORY Orii

One strength of Takaoka Copperware is its abundance of coloration techniques. Combining techniques and chemicals, including seidou, niiro, shudou, yaki-seidou, and ohaguro, makes it possible to produce dozens of color variations. This facility proposes products in a wide range of new color variations not just for artistic copperware, but for dining utensils, interior decorations, and exterior building materials. Its ANREALAGE×momentumfactory Orii work clothing has attracted considerable attention recently. The facility employs a youthful sensibility to tackle the challenge of future manufacturing.

Orii Chakusyoku-jo,530 Nagae,Takaoka-city,Toyama-prefecture

TEL.0766-23-9685

The three touching sounds of rin bells: “kan”, “otsu”, and “mon”

SHIMATANI SYOURYU KOUBOU

Founded in 1909, this facility makes and tunes keisu, rin, and daikin (bells and gongs) used in temples across Japan. Today, fewer than 10 craftspeople in Japan remain capable of hammering these massive bells from annealed metal. At least half of them are based in Takaoka. The pitch and frequency of the three notes of the bell, kan (tap note), otsu (middle note), and mon (lingering note), must be tuned perfectly at the final stage of production. Other popular products include delicate metal trays made using the technique of hammering called suzugami.

Applying traditional techniques to create a new brand of aluminum products

TAKATA SEISAKUSYO

Drawing on high levels of casting and polishing skills gained in making Buddhist altar fittings, Takata Factory produces contemporary products. Under the Shirokane and Takata Factory brands of interior items, it produces accessory stands, carafes, and other gift products. Under its Aldecor brand of aluminum tiles—the first aluminum tiles in Japan—it also produces and sells a wide range of exterior products, including tiles and bumper stops for parking lots. Takata Factory is also capable of handling all tasks ranging from prototype development to in-house finishing.

Creating contemporary products that incorporate dazzling mother-of-pearl inlays

MUSASHIGAWA KOUBOU

Founded in 1910, this facility inherits the traditional Takaoka lacquerware technique of aogai-nuri, designated a traditional handcraft by the government of Japan. This method of mother-of-pearl inlay creates patterns using abalone and other shells ground to about 0.1 mm in thickness and cut to various shapes. Recently, in addition to applying inlaid mother-of-pearl techniques to building materials, furniture, and metal objects, the facility has applied them to materials like glass vessels and even iPhone covers. The facility also creates new products through collaborations with designers. The goal is to match inlaid mother-of-pearl ware to contemporary ways of life.